Giải pháp kho tự động sử dụng công nghệ mới để vận chuyển hàng hóa hiệu quả. Họ cũng lưu trữ và quản lý hàng hóa trong kho, qua đó thay đổi cách thức vận hành kho bãi. Các giải pháp kho bãi tự động này giúp giảm thiểu lao động thủ công, giúp quy trình nhanh hơn và mượt mà hơn. Hiện tại, chỉ khoảng 5% kho bãi sử dụng các hệ thống tiên tiến này, nhưng tự động hóa đang tiếp tục cách mạng hóa hoạt động kho bãi.

Giải pháp kho tự động:

Giúp giảm thiểu lỗi và tăng tốc công việc

Tối ưu hóa việc sử dụng lực lượng lao động và tăng cường an toàn

Tăng tốc thực hiện đơn hàng và cắt giảm chi phí

Tự động hóa kho bãi hiện là một thành phần quan trọng trong logistics. Các giải pháp kho bãi tự động cho phép kho bãi mở rộng, cải thiện hiệu quả, tăng tính linh hoạt và độ chính xác.

Hệ thống kho tự động giúp kho vận hành nhanh hơn và an toàn hơn. Chúng cũng giúp mọi thứ chính xác hơn nhờ sử dụng robot, cảm biến và phần mềm thông minh. Những hệ thống này giúp tiết kiệm chi phí và giảm thiểu sai sót. Chúng sử dụng không gian hiệu quả hơn và giúp kho vận phát triển. Chúng cũng giúp kho vận hoạt động tốt hơn. Để bắt đầu áp dụng tự động hóa, các công ty nên xem xét nhu cầu của mình. Họ nên lập kế hoạch tốt và lựa chọn các nhà cung cấp đáng tin cậy như HUADE. Họ nên đào tạo nhân viên và cải thiện từng bước.

Tự động hóa kho bãi đã thay đổi cách thức hoạt động của ngành logistics. Nó sử dụng công nghệ mới để giúp công việc kho bãi trở nên dễ dàng và nhanh chóng hơn. Các công ty sử dụng giải pháp kho bãi tự động để theo dõi hàng tồn kho và cải thiện hiệu suất công việc. Những công nghệ này giúp kho bãi vận hành trơn tru và ít sai sót hơn.

Robot di động tự động (AMR) sử dụng cảm biến và trí tuệ nhân tạo. Chúng tự di chuyển trong kho, vận chuyển hàng hóa, thay đổi đường đi và làm việc cùng con người.

Xe tự hành (AGV) di chuyển theo lộ trình đã định sẵn, giúp vận chuyển hàng hóa trong kho một cách an toàn.

Hệ thống Pick-to-Light và Put-to-Light sử dụng đèn LED. Đèn báo hiệu cho công nhân biết vị trí cần nhặt hoặc đặt vật phẩm. Điều này giúp công nhân ít mắc lỗi hơn và làm việc nhanh hơn.

Công nghệ Voice Picking sử dụng nhận dạng giọng nói. Nó hướng dẫn công nhân chọn sản phẩm bằng giọng nói. Điều này cho phép công nhân sử dụng cả hai tay và làm việc nhanh hơn.

Hệ thống Phân loại Tự động sử dụng máy quét mã vạch, RFID và cảm biến. Những công cụ này giúp phân loại và vận chuyển hàng hóa đến đúng nơi.

Trí tuệ nhân tạo (AI) và máy học giúp dự đoán nhu cầu và quản lý hàng tồn kho tốt hơn.

Robot cộng tác (cobot) làm việc cùng con người. Chúng hỗ trợ việc nhặt, đóng gói và xếp chồng các vật dụng.

Thiết bị IoT và cảm biến thông minh giám sát hàng tồn kho và thiết bị, giúp công việc kho bãi trở nên dễ dàng hơn.

Hệ thống quản lý kho (WMS) là phần mềm chính. Chúng giúp quản lý hàng tồn kho và kết nối với các công cụ kỹ thuật số khác.

Hệ thống lưu trữ và lấy hàng tự động (AS/RS) giúp tiết kiệm không gian. Chúng giúp lưu trữ và lấy hàng tự động.

Mẹo: Các công ty có thể kết hợp các công nghệ này. Điều này giúp họ xây dựng các giải pháp kho tự động phù hợp với nhu cầu của mình.

Giải pháp kho tự động sử dụng các hệ thống và máy móc chuyên dụng. Chúng giúp lưu trữ, lấy hàng và vận chuyển hàng hóa mà không cần nhiều nhân công. Dưới đây là một số hệ thống quan trọng giúp kho vận hành hiệu quả hơn:

Các Hệ thống đưa đón pallet 4 chiều Sử dụng xe con thoi chạy bằng pin. Những xe con thoi này có thể di chuyển theo mọi hướng. Chúng di chuyển qua các kệ hàng mà không cần xe nâng. Công nhân đặt pallet vào đầu một kênh. Xe con thoi di chuyển pallet đến vị trí trống xa nhất. Nó sử dụng cảm biến để đặt pallet chính xác. Để lấy pallet trở lại, xe con thoi sẽ đưa pallet ra phía trước. Hệ thống này hoạt động với các hệ thống quản lý kho. Nó cũng sử dụng thang máy để di chuyển xe con thoi và pallet lên xuống. Hệ thống này tiết kiệm không gian bằng cách loại bỏ lối đi. Nó sử dụng cảm biến và phanh để giữ an toàn cho hàng hóa. Nó hoạt động với cả phương pháp kiểm kê FIFO và LIFO.

|

Diện mạo |

Sự miêu tả |

|---|---|

|

Chuyển động có hướng |

Di chuyển theo nhiều hướng để dễ dàng di chuyển. |

|

Mật độ lưu trữ |

Lưu trữ nhiều hơn bằng cách sử dụng ít không gian lối đi hơn. |

|

Tốc độ và hiệu quả |

Có thể di chuyển nhiều hàng hóa một cách nhanh chóng. |

|

Tích hợp |

Hoạt động tốt với hệ thống quản lý kho. |

|

Khả năng mở rộng và tính linh hoạt |

Có thể thay đổi khi kho mở rộng. |

|

Tính năng an toàn |

Có cảm biến và phanh để đảm bảo an toàn. |

|

Ứng dụng công nghiệp |

Được sử dụng trong bán lẻ, kho lạnh, thực phẩm và nhà máy. |

|

Phương pháp kiểm kê |

Hoạt động với phương pháp kiểm kê FIFO và LIFO. |

Hệ thống cẩu xếp AS/RS Sử dụng xe nâng một trụ. Những xe này di chuyển lên, xuống và qua các lối đi. Chúng lưu trữ và lấy hàng từ những nơi cao. Hệ thống này đáng tin cậy và tiết kiệm không gian. Hệ thống cẩu trục + cẩu xếp chồng Chia nhỏ công việc. Cẩu xếp chồng di chuyển lên xuống và dọc theo lối đi. Xe con thoi cơ giới di chuyển hàng hóa theo chiều ngang trong các kênh lưu trữ. Nhiều xe con thoi có thể hoạt động cùng lúc. Điều này giúp hệ thống nhanh hơn và linh hoạt hơn. Việc bổ sung thêm xe con thoi sẽ hữu ích khi có nhiều đơn hàng hơn. Cả hai hệ thống đều hoạt động với hệ thống quản lý kho. Chúng phù hợp với những nơi có nhiều pallet và công việc nhanh chóng.

Hệ thống Radio Shuttle Di chuyển pallet trong các lối đi kho sâu. Nhân viên sử dụng điều khiển từ xa để khởi động xe đưa đón. Xe đưa đón sẽ đưa pallet đến đúng vị trí. Các giải pháp kho tự động này giúp tiết kiệm không gian và sử dụng ít xe nâng hơn. Chúng cũng giúp kho an toàn hơn. Hệ thống Radio Shuttle hoạt động với hệ thống quản lý kho để theo dõi hàng tồn kho và xử lý đơn hàng.

Các công cụ tự động hóa kỹ thuật số đóng vai trò quan trọng trong tự động hóa kho bãi. Hệ thống quản lý kho bãi thực hiện các công việc như theo dõi dữ liệu, hàng tồn kho, đơn hàng và nhân công. Các cảm biến như RFID và máy quét mã vạch cho biết vị trí hàng hóa theo thời gian thực. Chúng cũng giúp phân loại hàng hóa tự động. Bộ điều khiển logic lập trình (PLC) điều khiển các máy móc như băng tải và hệ thống lưu trữ. Những công cụ này giúp giảm thiểu công việc thủ công và sai sót, đồng thời giúp nhân viên làm việc tốt hơn và an toàn hơn.

Robot trong hệ thống kho tự động giúp lưu trữ và lấy hàng. Chúng cũng giúp lấy hàng và tiết kiệm thời gian cho công nhân. Robot vận chuyển được hỗ trợ bởi AI sử dụng cảm biến để di chuyển qua chướng ngại vật. Chúng có thể thay đổi đường đi nếu cần. Robot cộng tác hỗ trợ con người bằng cách thực hiện các nhiệm vụ khó khăn. Điều này giúp công việc dễ dàng và an toàn hơn. Robot tự động giúp xử lý đơn hàng nhanh hơn và công việc trôi chảy hơn.

Giải pháp kho tự động Modula sử dụng hệ thống mô-đun, robot và công cụ kỹ thuật số. Các giải pháp này có thể thay đổi tùy theo nhu cầu kinh doanh, giúp kho vận hoạt động hiệu quả và phát triển dễ dàng.

HUADE là công ty hàng đầu về giải pháp kho tự động. Công ty đã được cấp bằng sáng chế cho robot di chuyển bốn chiều. Robot này giúp các kho lưu trữ nhiều hơn, sử dụng không gian hiệu quả hơn và tiết kiệm chi phí hơn. HUADE cung cấp các hệ thống lưu trữ và lấy hàng tự động với AI cho kho thông minh. Các giải pháp của họ sử dụng công nghệ theo dõi RFID, xe tự hành và quản lý kho hàng trên nền tảng đám mây. Khách hàng yêu thích HUADE vì sản phẩm tốt và dịch vụ tận tâm.

Ghi chú: HUADE nổi tiếng với những ý tưởng mới mẻ và độ tin cậy cao. Nhiều doanh nghiệp tin tưởng họ về hệ thống kho tự động tiên tiến.

Tự động hóa kho hàng mang lại nhiều lợi ích cho các kho hàng ngày nay. Các công ty cho biết họ làm được nhiều việc hơn, với sản lượng tăng khoảng 25% sau khi sử dụng hệ thống kho hàng tự động. Chi phí nhân công và sản xuất giảm 25–30%. Việc kiểm soát hàng tồn kho được cải thiện nhờ theo dõi thời gian thực và tự động bổ sung hàng. Các giải pháp kho hàng tự động giúp ngăn ngừa sai sót, đạt độ chính xác đơn hàng lên đến 99,9%. Robot và hệ thống lưu trữ tự động giúp sử dụng không gian hiệu quả hơn, giúp lưu trữ hiệu quả hơn 20–40%. Đơn hàng được xử lý nhanh hơn, và một số công ty như Amazon đã chứng kiến thời gian đặt hàng giảm 25%. Những lợi ích chính này cũng cho phép các kho hàng phát triển nhanh chóng và làm hài lòng khách hàng.

|

Tiết kiệm chi phí |

Thống kê / Ví dụ |

|---|---|

|

Giảm chi phí lao động |

Giảm 20-40%; một công ty đã cắt giảm chi phí lao động tới 40% trong 2 năm |

|

Giảm chi phí hoạt động |

Tiết kiệm 15-25% trong 18 tháng |

|

Độ chính xác khi chọn |

Độ chính xác trên 99,5%, do đó ít sai sót tốn kém hơn |

|

Tiết kiệm diện tích sàn |

Tiết kiệm tới 40% diện tích sàn cần thiết |

|

Giảm chi phí liên quan đến chấn thương |

Ít chấn thương hơn vì ít công việc thủ công hơn |

|

Dòng thời gian ROI |

Tiền chi ra thường được kiếm lại sau 12-24 tháng |

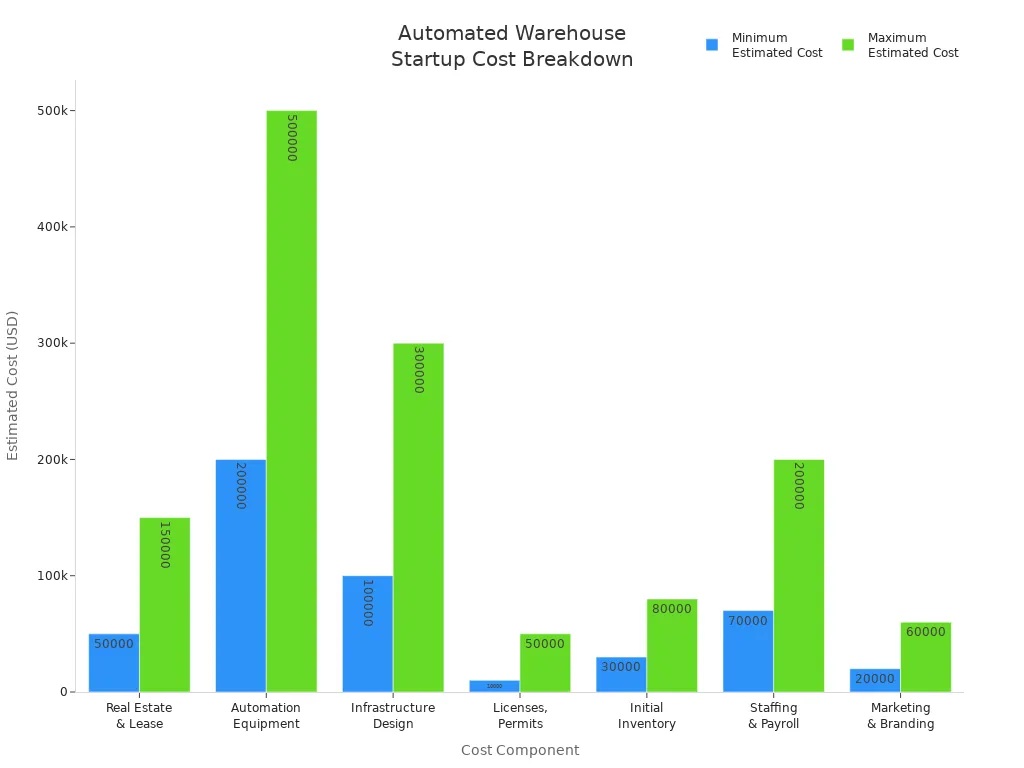

Tự động hóa kho hàng có một số thách thức. Việc kết nối các hệ thống quản lý kho, robot và thiết bị IoT có thể gặp khó khăn. Chi phí ban đầu cho thiết bị và công nghệ kho hàng tự động khá cao. Người lao động cần được đào tạo và hỗ trợ, và một số người lo lắng về việc mất việc. Hệ thống tự động cần được bảo trì thường xuyên để duy trì hoạt động. Bảo mật dữ liệu càng quan trọng hơn với các thiết bị được kết nối. Kho hàng phải có khả năng phát triển và thay đổi khi cần thiết. Các công ty cần cân bằng chi phí tự động hóa với khoản tiết kiệm dài hạn và lập kế hoạch cho những thay đổi để tự động hóa hoạt động hiệu quả.

Để có một kho hàng hoàn toàn tự động, các công ty nên thực hiện các bước sau:

Xem xét nhu cầu của kho và kiểm tra hàng tồn kho, đơn đặt hàng và cách thức thực hiện công việc.

Tìm ra vấn đề và đưa ra giải pháp tự động hóa phù hợp với từng nhu cầu.

Hãy nghĩ về cách hệ thống có thể phát triển và thay đổi trong tương lai.

Hãy kiểm tra xem chi phí có xứng đáng hay không bằng cách xem xét những lợi ích mà nó mang lại.

Hãy tìm đến những nhà cung cấp như HUADE để được hỗ trợ và có kinh nghiệm.

Lập kế hoạch từng bước, đào tạo nhân viên và bắt đầu bằng những thử nghiệm nhỏ.

Hãy quan sát cách mọi thứ hoạt động và tiếp tục cải tiến kho tự động.

Hệ thống kho tự động thay đổi cách thức vận hành kho. Chúng giúp kho hàng hoạt động hiệu quả hơn, chính xác hơn và an toàn hơn. Tự động hóa cho phép nhân viên làm việc hiệu quả hơn và ít mắc lỗi hơn. Nó cũng giúp theo dõi hàng tồn kho tốt hơn. Các công ty nên xem xét cả ưu và nhược điểm của tự động hóa. Điều này giúp họ lựa chọn giải pháp tốt nhất cho mình. Quản lý kho cần suy nghĩ về những gì họ cần. Họ nên tìm hiểu các giải pháp kho tự động từ các công ty uy tín như HUADE.

Hệ thống kho tự động giúp kho vận hành tốt hơn. Chúng giúp công việc nhanh hơn, an toàn hơn và chính xác hơn. Các hệ thống này di chuyển, lưu trữ và quản lý hàng hóa với ít sự can thiệp của con người hơn.

Hệ thống tự động sử dụng cảm biến, phần mềm và robot để theo dõi hàng hóa. Chúng hướng dẫn công nhân và nhiệm vụ để giảm thiểu sai sót, giúp đơn hàng chính xác hơn.

Có. Các nhà cung cấp tạo ra giải pháp kho tự động cho mọi quy mô kho. Các công ty sẽ lựa chọn hệ thống phù hợp với nhu cầu của mình.

Bản quyền @ 2026 Nanjing Huayide Logistics Technology Co., Ltd. Tất cả quyền được bảo lưu.

mạng được hỗ trợ

mạng được hỗ trợ

SITEMAP / Xml / Blog / Chính sách bảo mật